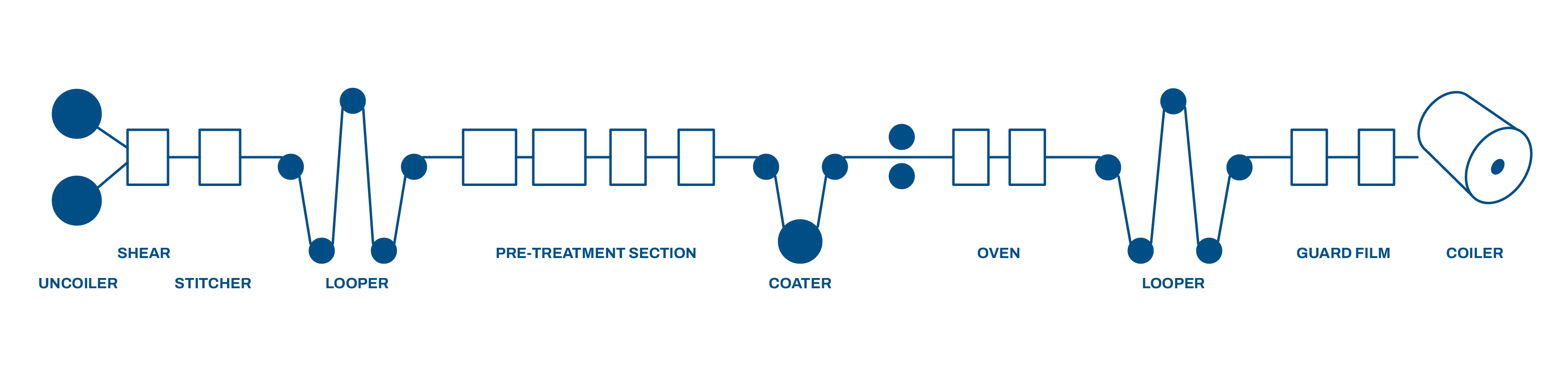

Our advanced processing and coating techniques ensure superior adhesion of the colour coating to the base metal, delivering high performance even during roll forming, bending and other fabrication stages. Our innovative ‘two coat-two bake’ process involves two cycles of coating and baking following a thorough pre-treatment, resulting in a durable and uniform finish.

Our extensive range of pre-painted steel sheets & coils are made of high-quality carbon steel, and are used for diverse industry applications. Customisations are done as per precise buyer requirements.

We focus on maintaining world-class product quality standards, by following an agile, systematic, state-of-the-art manufacturing process. Advanced processing and coating techniques are implemented to ensure that the coating adheres firmly to the base metal and does not peel off during roll forming, bending or any other process.

A 'two coat-two bake' process, that involves two steps of coating and baking after the sheet has undergone pre-treatment, helps us optimise product quality. The substrate metal is first coated with primer to allow better adhesion with the second coating of paint, which gives the product a vibrant look and provides additional protection against extreme weather conditions, improving its longevity.

With continuous improvement in focus, we deliver significant competitive advantages to our customers worldwide.