Years of Experience

Team Strength

Production Capacity

Our manufacturing company boasts a state-of-the-art infrastructure designed to meet the highest standards of efficiency, quality, and innovation. Equipped with cutting-edge machinery, automated production lines, and advanced quality control systems, we ensure seamless operations across all stages of manufacturing. Our facilities are strategically located to optimise supply chain logistics, reducing lead times and ensuring timely delivery. With a dedicated focus on sustainability, we also incorporate eco-friendly technologies to minimise our environmental impact while maintaining the highest levels of production excellence. This robust infrastructure supports our commitment to delivering superior products to our clients.

In order to progressively strengthen our pan-India supply network, we have set up manufacturing facilities, warehouses, stock yards and other units across the country.

MCMIL’s core operations are based at its advanced steel facility in Kutch, Gujarat, featuring a sophisticated Galvanising Line (production capacity: 132,000 TPA) and a modern Colour Coating Line (production capacity: 86,000 TPA), supported by advanced, high-performance machinery. Both lines are fully automated and engineered for micron-level precision, ensuring consistent, premium-grade steel coils and sheets.

Located near Kandla and Mundra ports, the facility offers a key logistical advantage, enabling efficient service to domestic and international markets and reinforcing MCMIL’s position as a competitive, high-quality supplier.

MCMIL has a facility in Bhopal, MP, where we run a contract manufacturing operation with Reckitt Benckiser, to produce Ultramarine Blue Powder. The facility is highly automated with no requirement for human interaction with the system in the intermediate production steps between unloading of the material to the final end packaging.

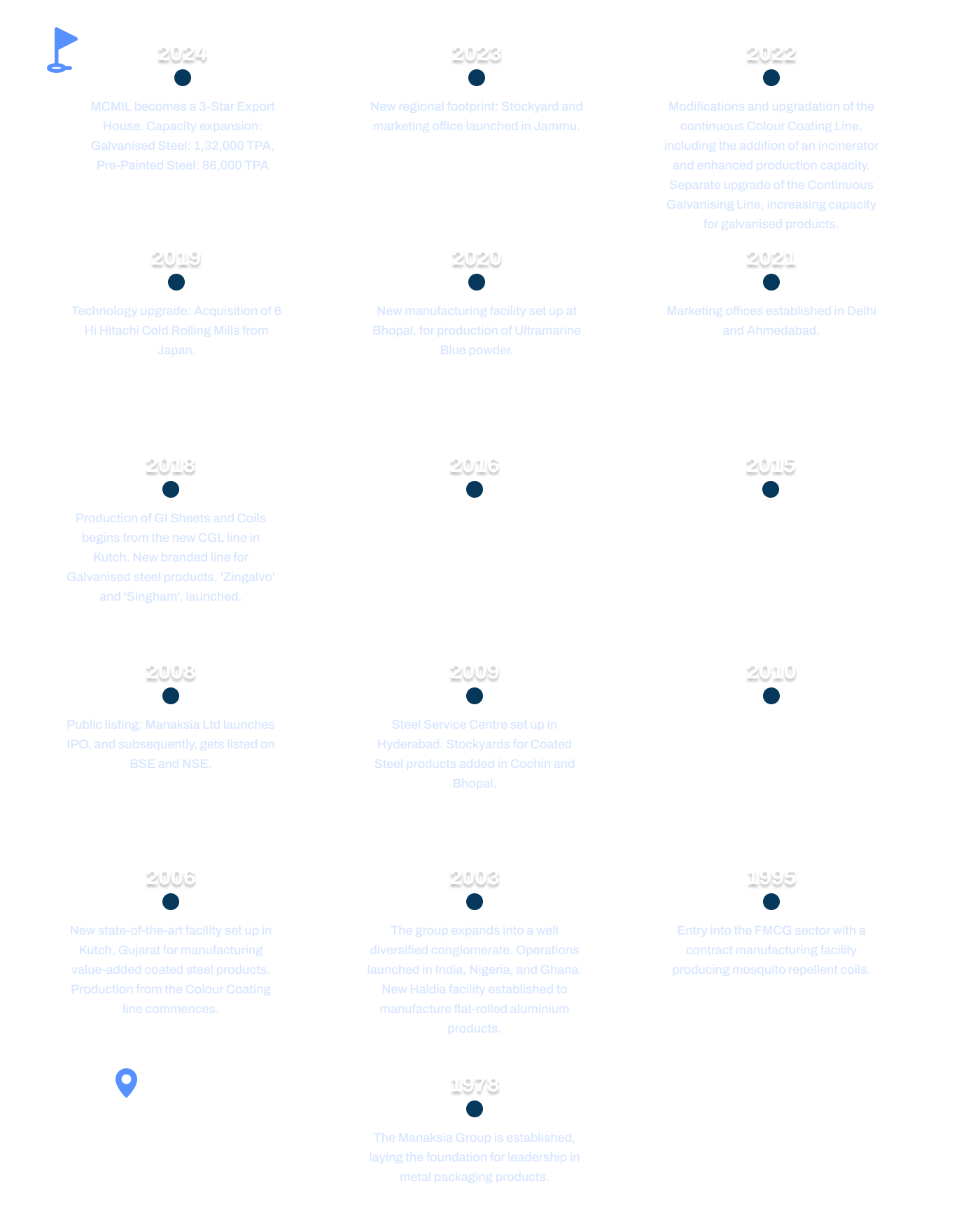

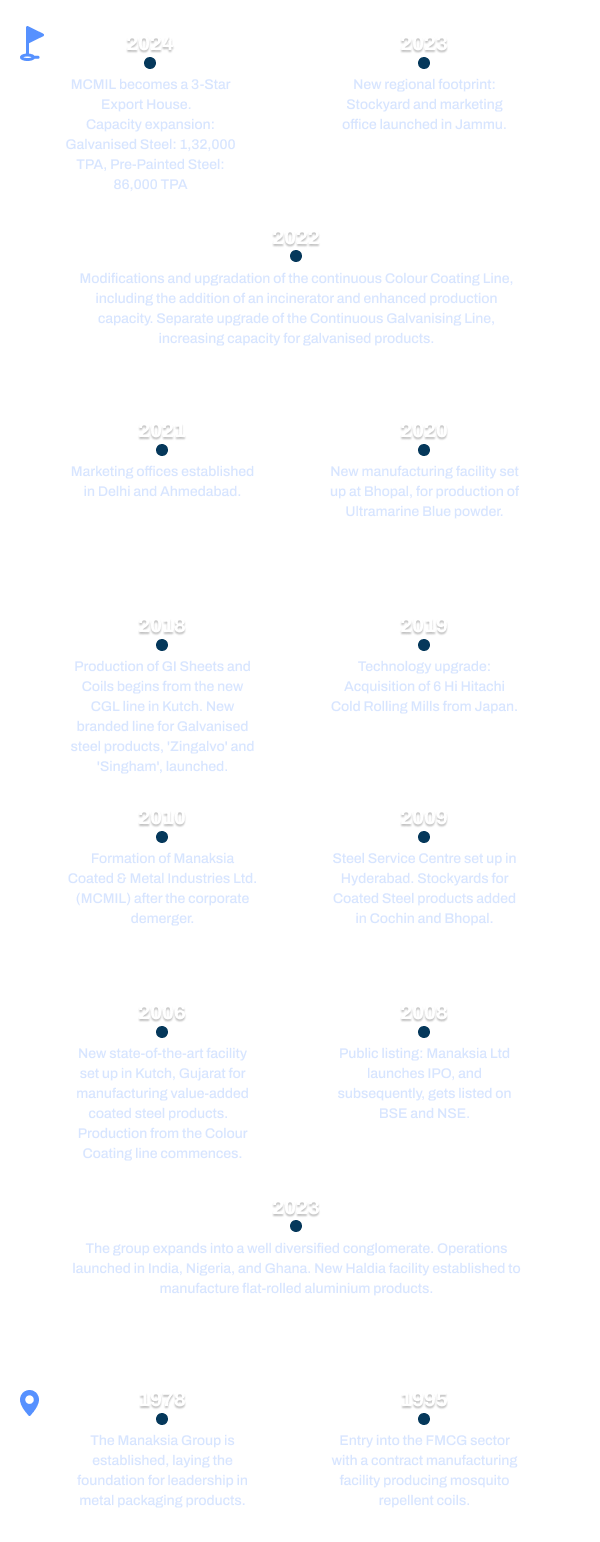

Across decades, we have been right at the forefront of the coated metals sector, growing continuously and serving clients across boundaries.

Equipped with automated production lines, precision machinery, and advanced quality control systems, at MCMIL we ensure consistency and excellence at every stage of production.

Our strategically located facilities help us optimise logistics, reduce lead times, and maintain timely deliveries. With a strong focus on sustainability, we also integrate eco-friendly technologies that minimise environmental impact without compromising on performance.

This robust setup reflects our core commitment—to deliver high-quality, reliable coated metal products that meet the evolving needs of our customers in India and around the world.

Our commitment to quality excellence is underlined by several prestigious product and process certifications.

We follow a streamlined production process that does not hamper the environmental integrity in any way. Steps are taken to cut down on both energy and fuel consumption, and manage overall manufacturing costs.

With a unified vision and strategic decision-making, our core leadership team constantly leads us towards success.

We are constantly driven by our core business values that serve as the pillars of our growth over time.

We prioritise skill development and overall welfare of our internal stakeholders to help them sync individual goals with organisational objectives.

With a combination of advanced production infrastructure, streamlined workflows and strategic decision-making, we strive to set newer, higher quality benchmarks.

Staying true to our business promises and commitments is of immense importance to us. At every point, we look to meet & surpass customer expectations.

Through knowledge-sharing and resource utilisation, we constantly strive to become incrementally better everyday.

We follow a strong code of ethics at all times. Every action we take is powered by honesty, transparency and accountability.

We currently have two registered subsidiaries supporting our growth and diversification strategy.

From coated metals to FMCG, our subsidiaries extend our vision into other categories while aligning with our core values of quality, scale and innovation.