With a combination of a state-of-the-art galvanising line, other production infrastructure, and agile manufacturing standards, MCMIL is a globally recognised manufacturer of galvanised steel.

Our precision-engineered and quality-assured range of galvanised steel products find widespread application in different industries. With high performance, superior longevity and competitive pricing, our products offer the best value for money.

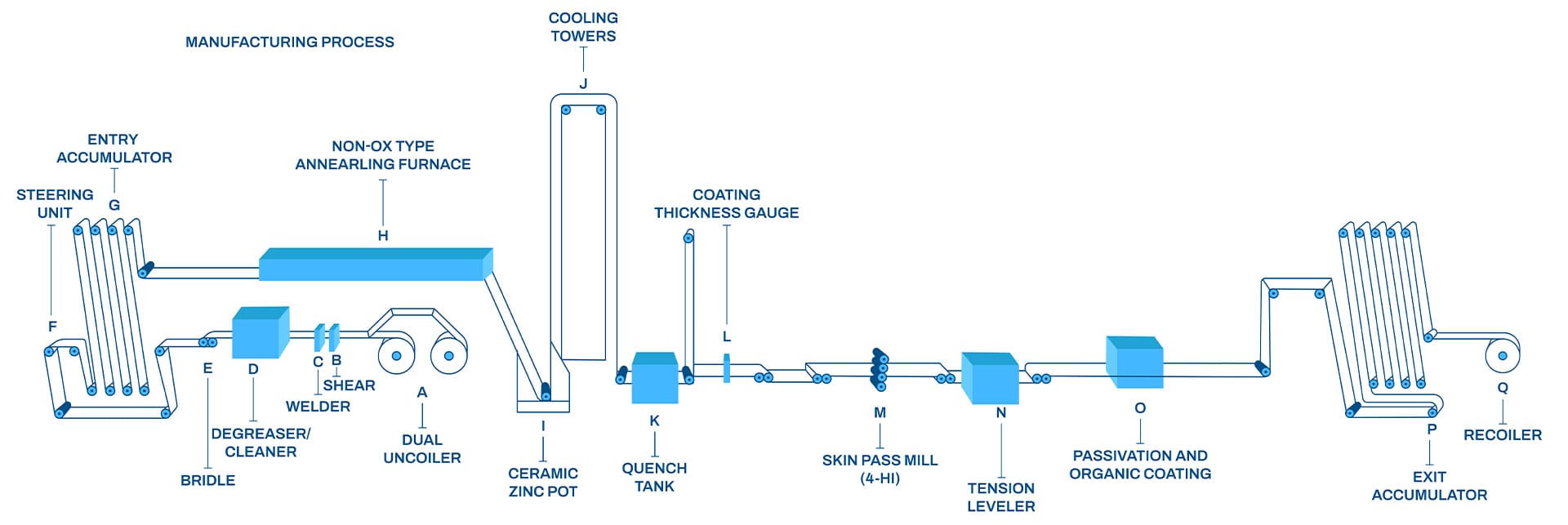

By adhering to a streamlined, advanced, and automated manufacturing process, we ensure optimal quality of our entire product range. Our state-of-the-art continuous galvanising line enables excellent surface cleaning, annealing, and preparation of the steel strip before it enters the hot dip galvanising zinc bath via a NON-OX furnace. The zinc bath composition is controlled to achieve ideal coating properties and enhanced zinc adhesion in order to create a pacification coat around the steel, keeping moisture out and preventing corrosion.

The zinc coating thickness is controlled to the highest grades of precision through an automated air-knife system and a perfect finish and flatness to the surface is achieved through a skin-pass mill and a tension leveler. Post-surface treatment in the form of chromating or application of AFP and organic coatings is done to further enhance the corrosion resistance and also provide sheen on the surface. The whole process is computer aided to help achieve higher levels of uniformity and perfection.

With continuous improvement in focus, we deliver significant competitive advantages to our customers worldwide.